CERAVER, a former subsidiary of the Alcatel-Alsthom group, began its activity in orthopaedics thanks to the chance meeting of a materials engineer, Daniel BLANQUAERT, and an orthopaedic surgeon, Pierre BOUTIN. This meeting marked the start of a series of innovations that would revolutionise the world of hip replacement orthopaedics.

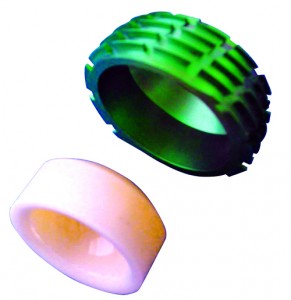

This is how the invention of the alumina-alumina articulation total hip prosthesis came about, along with discovering the significant potential of titanium alloy TiAl6V4